25 марта, 2021

Virtual reality for industrial enterprises

Leading industrial enterprises around the world have adapted VR to their needs. Since there are no ready-made narrow-profile virtual solutions for enterprises, companies have to develop their own product taking into account the peculiarities of production, independently solve the problems of integration, conversion and scaling.

In 2014, statistics showed less than a million users of «virtual reality». Analysts from Zeon Market Research estimated that in 2016, the VR market volume amounted to about $ 2 billion, by 2022 it will reach the $ 26.8 billion mark.

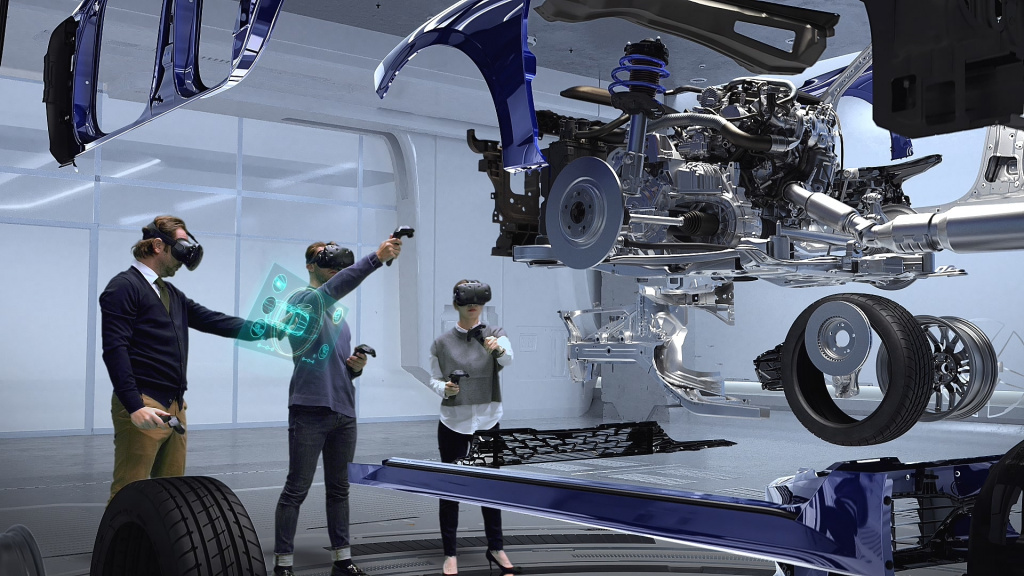

VR is a technology that immerses the user in an artificially simulated environment created with the help of a computer. The user interacts with the VR space using virtual glasses or a helmet, controllers or suits, gloves with tactile feedback.

Virtual reality in industry is used for introductory and targeted briefings, training to work on complex and technological equipment, and demonstration of the enterprise infrastructure. Efficiency is achieved due to the ability of VR to immerse users in realistic situations and recreate complex workflows.

It is necessary to understand that the introduction of virtual reality into the production process is part of the digital transformation of the enterprise and radically changes the established approach to its work. Therefore, the introduction of VR requires a well-thought-out implementation strategy, preliminary analysis and collection of information, monitoring the effectiveness of solutions. It is necessary to understand how the technology will be scaled, adjusted or configured for specific business processes.

In order to make a decision on the use of a VR tool in production, it is necessary to answer the following questions:

What goals does the company plan to achieve through the introduction of VR?

How does virtual reality contribute to achieving goals?

When solving what tasks of the enterprise, virtual reality will be most effective?

What benefits, including economic benefits, does the use of VR bring?

How, where and on what VR simulator will employees study and work?

Which of the specialists will be responsible for the process of learning or working with VR?

How will the piloting process be organized, what indicators should be taken into account?

Virtual Reality Simulators in Workflow Training

VR simulators can be scaled to an unlimited number of employees. With VR-learning, associative connections are created between theory and practice: a person learns new knowledge and immediately gets the opportunity to apply it in the virtual space. Virtual simulators teach new employees of the company the rules of working with expensive or dangerous equipment without risks to life, the probability of failure or harm to the environment.

You can practice in VR countless times, until the actions are brought to automatism. The effect of complete immersion and the inability to be distracted by extraneous stimuli allows the specialist to assimilate information several times faster and more effectively than with traditional training. VR makes it possible to train remotely, without the participation of mentors and to conduct employee certification, saving time, physical and financial resources.

Advantages of VR

+ 32%

Increasing the productivity of the workforce

30%

Reducing errors during operation

-25%

Reducing the time required to complete tasks

More than 85% of the educational material is successfully assimilated

One of the examples of a VR training simulator is a virtual simulator developed by Big Dream Lab for training controllers of the technical condition of vehicles at enterprises engaged in the transportation of people and goods. With the help of the simulator, the specialist is immersed in a virtual environment for training and practicing the skills of conducting a pre-trip inspection of transport. According to the instructions, the employee must master the rules and procedure for checking the serviceability of the machine and its equipment. The simulator gives the user the opportunity to repeatedly conduct a virtual inspection of transport, work out mistakes and consolidate the acquired skills.

Why are VR training simulators effective?

- Practical skills

- Formation of skills for managing technological processes at hazardous production facilities.

- Safety

- Obtaining a holistic view of the production technology in a safe environment and without going to the work site.

- Economy

- Reduction of material costs for training by an average of 50% (no need to purchase training equipment and physical stands, separation of personnel from production for the training period).

- Diving

- Increasing interest in the learning process and deep immersion in the material. More than 85% of the educational material is successfully assimilated.

VR technologies in industrial safety

Emergency situations at enterprises require a quick response of specialists and prompt coordination of solutions to eliminate their consequences. Virtual reality training allows users to feel the consequences of accidents and emergencies and take actions to eliminate them. An employee can climb to a height, interact with dangerous objects and phenomena, and most importantly, feel what is happening. VR simulation has a great emotional impact on employees, encouraging them to think independently in critical circumstances and follow work instructions.

The virtual reality technology has been studied in detail by psychologists and methodologists: after working out an emergency in virtual reality, employees cope with emergency situations more quickly and remember the sequence of actions better.

Virtual tours of the production

Virtual tours of the production allow you to take a tour to remote, dangerous or closed objects. Such solutions can be used to demonstrate work processes to customers, at exhibitions or for staff training. For this purpose, in addition to creating a 3D production environment, the technology of shooting 360-degree video can be used, which can also produce the necessary effect on the user.

With the transition to «digital rails», all industrial enterprises will eventually have to.

Big Dream Lab will help your company make a painless transition to digitalization by developing virtual reality simulators. Creating a solution for your company will include the main stages:

- Definition of the task that the simulator should solve.

To do this, an analysis of the company’s activities is carried out and problem points are identified that prevent a full-fledged production process.

Creating a user experience scenario: the algorithm of the user’s action is prescribed from the beginning to the end.

At this stage, the need for additional functions of the simulator is also stipulated: recording, analysis and evaluation of user actions in automatic mode, integration with any company systems, creating a computer version of the program, the presence of the «browser» mode, and others.

- Creating a technical task based on the collected information, according to which the simulator is gradually developed in the future. As a rule, the minimum viable product (MVP) is produced first, which is demonstrated and agreed with the customer, and then the simulator functions are already added.

Within 1-3 months, depending on the complexity of the virtual environment simulator, your company will receive a ready-made solution for integration in the enterprise.